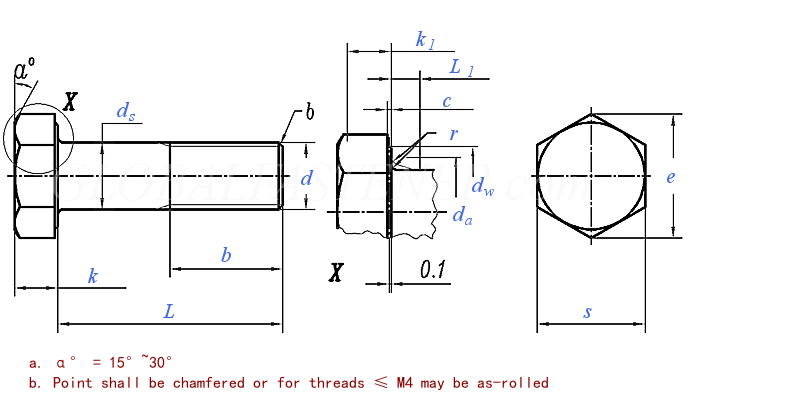

Héichfest Sechskantschraube Din 931 / ISO4014 CL 8.8

| Produkter Numm | SECHSATZBOHR DIN 931/ISO4014 HALLEFGEWIND |

| Standard | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| Grad | Stolqualitéit: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A, A325, A490, |

| Veraarbechtung | Zink (Giel, Wäiss, Blo, Schwaarz), Hopfen-Dip-Galvaniséiert (HDG), Schwaarzoxid, Geomet, Dacroment, Eloxéierung, Vernickelt, Zink-Vernickelt |

| Produktiounsprozess | M2-M24: Kalt Schmieden, M24-M100 Waarmschmieden, Bearbechtung a CNC fir personaliséiert Befestigungselementer |

| Personaliséiert Produkter Liwwerzäit | 30-60 Deeg, |

| Schraufgewinde | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | Spillplaz | 0,35 | 0,4 | 0,45 | 0,5 | 0,6 | 0,7 | 0,8 | 1 | 1 | 1,25 | 1.5 | 1,75 | |

| b | L≤125 | 9 | 10 | 11 | 12 | 13 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | |

| 125 L≤200 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 26 | 28 | 32 | 36 | ||

| L>200 | 28 | 29 | 30 | 31 | 32 | 33 | 35 | 37 | 39 | 41 | 45 | 49 | ||

| c | maximal | 0,25 | 0,25 | 0,25 | 0,4 | 0,4 | 0,4 | 0,5 | 0,5 | 0,6 | 0,6 | 0,6 | 0,6 | |

| Minutten | 0,1 | 0,1 | 0,1 | 0,15 | 0,15 | 0,15 | 0,15 | 0,15 | 0,15 | 0,15 | 0,15 | 0,15 | ||

| da | maximal | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| ds | max=nominal Gréisst | 1.6 | 2 | 2,5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | |

| Klass A | Minutten | 1,46 | 1,86 | 2,36 | 2,86 | 3.32 | 3,82 | 4,82 | 5,82 | 6,78 | 7,78 | 9,78 | 11,73 | |

| Klass B | Minutten | 1,35 | 1,75 | 2,25 | 2,75 | 3.2 | 3.7 | 4.7 | 5.7 | 6,64 | 7,64 | 9,64 | 11,57 | |

| dw | Klass A | Minutten | 2,54 | 3,34 | 4.34 | 4,84 | 5.34 | 6.2 | 7.2 | 8,88 | 9,63 | 11,63 | 14,63 | 16,63 |

| Klass B | Minutten | 2,42 | 3.22 | 4.22 | 4,72 | 5.22 | 6.06 | 7.06 | 8,74 | 9,47 | 11.47 | 14.47 | 16.47 | |

| e | Klass A | Minutten | 3.41 | 4.32 | 5,45 | 6.01 | 6,58 | 7,66 | 8,79 | 11.05 | 12.12 | 14.38 | 17,77 | 20.03 |

| Klass B | Minutten | 3.28 | 4.18 | 5.31 | 5,88 | 6,44 | 7,5 | 8,63 | 10,89 | 11,94 | 14.2 | 17,59 | 19,85 | |

| L1 | maximal | 0,6 | 0,8 | 1 | 1 | 1 | 1.2 | 1.2 | 1.4 | 1.4 | 2 | 2 | 3 | |

| k | Nominal Gréisst | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7,5 | |

| Klass A | maximal | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2,925 | 3,65 | 4.15 | 4,95 | 5,45 | 6,58 | 7,68 | |

| Minutten | 0,975 | 1.275 | 1,575 | 1,875 | 2.275 | 2,675 | 3,35 | 3,85 | 4,65 | 5.15 | 6.22 | 7.32 | ||

| Klass B | maximal | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3,74 | 4.24 | 5.04 | 5,54 | 6,69 | 7,79 | |

| Minutten | 0,9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3,76 | 4,56 | 5.06 | 6.11 | 7.21 | ||

| k1 | Klass A | Minutten | 0,68 | 0,89 | 1.1 | 1.31 | 1,59 | 1,87 | 2,35 | 2.7 | 3.26 | 3,61 | 4,35 | 5.12 |

| Klass B | Minutten | 0,63 | 0,84 | 1,05 | 1,26 | 1,54 | 1,82 | 2.28 | 2,63 | 3.19 | 3,54 | 4.28 | 5.05 | |

| r | Minutten | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,2 | 0,2 | 0,25 | 0,25 | 0,4 | 0,4 | 0,6 | |

| s | max=nominal Gréisst | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| Klass A | Minutten | 3.02 | 3,82 | 4,82 | 5.32 | 5,82 | 6,78 | 7,78 | 9,78 | 10,73 | 12,73 | 15,73 | 17,73 | |

| Klass B | Minutten | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6,64 | 7,64 | 9,64 | 10,57 | 12,57 | 15,57 | 17,57 | |

| Längt vum Fuedem b | - | - | - | - | - | - | - | - | - | - | - | - | ||

| Schraufgewinde | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | Spillplaz | 2 | 2 | 2,5 | 2,5 | 2,5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| b | L≤125 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | - | - | - | |

| 125 L≤200 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | ||

| L>200 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | 109 | ||

| c | maximal | 0,6 | 0,8 | 0,8 | 0,8 | 0,8 | 0,8 | 0,8 | 0,8 | 0,8 | 0,8 | 1 | 1 | |

| Minutten | 0,15 | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 | 0,3 | 0,3 | ||

| da | maximal | 15.7 | 17,7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33,4 | 36,4 | 39,4 | 42,4 | 45,6 | |

| ds | max=nominal Gréisst | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| Klass A | Minutten | 13,73 | 15,73 | 17,73 | 19,67 | 21,67 | 23,67 | - | - | - | - | - | - | |

| Klass B | Minutten | 13,57 | 15,57 | 17,57 | 19.48 | 21.48 | 23.48 | 26,48 | 29,48 | 32,38 | 35,38 | 38,38 | 41,38 | |

| dw | Klass A | Minutten | 19,64 | 22,49 | 25.34 | 28.19 | 31,71 | 33,61 | - | - | - | - | - | - |

| Klass B | Minutten | 19.15 Auer | 22 | 24,85 | 27,7 | 31.35 | 33,25 | 38 | 42,75 | 46,55 | 51.11 | 55,86 | 59,95 | |

| e | Klass A | Minutten | 23.36 | 26,75 | 30.14 | 33,53 | 37,72 | 39,98 | - | - | - | - | - | - |

| Klass B | Minutten | 22,78 | 26.17 | 29,56 | 32,95 | 37,29 | 39,55 | 45,2 | 50,85 | 55,37 | 60,79 | 66,44 | 71,3 | |

| L1 | maximal | 3 | 3 | 3 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 | 8 | |

| k | Nominal Gréisst | 8.8 | 10 | 11,5 | 12,5 | 14 | 15 | 17 | 18,7 | 21 | 22,5 | 25 | 26 | |

| Klass A | maximal | 8,98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| Minutten | 8,62 | 9,82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| Klass B | maximal | 9.09 | 10.29 | 11,85 | 12,85 | 14.35 Auer | 15.35 | 17.35 Auer | 19.12 | 21.42 | 22,92 | 25,42 | 26.42 | |

| Minutten | 8,51 | 9,71 | 11.15 Auer | 12.15 Auer | 13,65 | 14,65 | 16,65 | 18.28 | 20,58 | 22.08 | 24,58 | 25,58 | ||

| k1 | Klass A | Minutten | 6.03 | 6,87 | 7.9 | 8.6 | 9,65 | 10.35 | - | - | - | - | - | - |

| Klass B | Minutten | 5,96 | 6.8 | 7,81 | 8,51 | 9,56 | 10.26 | 11,66 | 12.8 | 14.41 | 15.46 | 17.21 | 17,91 | |

| r | Minutten | 0,6 | 0,6 | 0,6 | 0,8 | 0,8 | 0,8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | max=nominal Gréisst | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| Klass A | Minutten | 20,67 | 23,67 | 26,67 | 29,67 | 33,38 | 35,38 | - | - | - | - | - | - | |

| Klass B | Minutten | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53,8 | 58,8 | 63.1 | |

| Längt vum Fuedem b | - | - | - | - | - | - | - | - | - | - |

|

| ||

| Schraufgewinde | (M45) | M48 | (M52) | M56 | (M60) | M64 |

|

|

|

|

|

| ||

| P | Spillplaz | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 |

|

|

|

|

|

| |

| b | L≤125 | - | - | - | - | - | - |

|

|

|

|

|

| |

| 125 L≤200 | 102 | 108 | 116 | - | - | - |

|

|

|

|

|

| ||

| L>200 | 115 | 121 | 129 | 137 | 145 | 153 |

|

|

|

|

|

| ||

| c | maximal | 1 | 1 | 1 | 1 | 1 | 1 |

|

|

|

|

|

| |

| Minutten | 0,3 | 0,3 | 0,3 | 0,3 | 0,3 | 0,3 |

|

|

|

|

|

| ||

| da | maximal | 48,6 | 52,6 | 56,6 | 63 | 67 | 71 |

|

|

|

|

|

| |

| ds | max=nominal Gréisst | 45 | 48 | 52 | 56 | 60 | 64 |

|

|

|

|

|

| |

| Klass A | Minutten | - | - | - | - | - | - |

|

|

|

|

|

| |

| Klass B | Minutten | 44,38 | 47,38 | 51,26 | 55,26 | 59,26 | 63,26 |

|

|

|

|

|

| |

| dw | Klass A | Minutten | - | - | - | - | - | - |

|

|

|

|

|

|

| Klass B | Minutten | 64,7 | 69,45 | 74,2 | 78,66 | 83,41 | 88,16 |

|

|

|

|

|

| |

| e | Klass A | Minutten | - | - | - | - | - | - |

|

|

|

|

|

|

| Klass B | Minutten | 76,95 | 82,6 | 88,25 | 93,56 | 99,21 | 104,86 |

|

|

|

|

|

| |

| L1 | maximal | 8 | 10 | 10 | 12 | 12 | 13 |

|

|

|

|

|

| |

| k | Nominal Gréisst | 28 | 30 | 33 | 35 | 38 | 40 |

|

|

|

|

|

| |

| Klass A | maximal | - | - | - | - | - | - |

|

|

|

|

|

| |

| Minutten | - | - | - | - | - | - |

|

|

|

|

|

| ||

| Klass B | maximal | 28.42 | 30,42 | 33,5 | 35,5 | 38,5 | 40,5 |

|

|

|

|

|

| |

| Minutten | 27,58 | 29,58 | 32,5 | 34,5 | 37,5 | 39,5 |

|

|

|

|

|

| ||

| k1 | Klass A | Minutten | - | - | - | - | - | - |

|

|

|

|

|

|

| Klass B | Minutten | 19.31 | 20,71 | 22,75 | 24.15 | 26.25 | 27,65 |

|

|

|

|

|

| |

| r | Minutten | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

|

|

|

|

|

| |

| s | max=nominal Gréisst | 70 | 75 | 80 | 85 | 90 | 95 |

|

|

|

|

|

| |

| Klass A | Minutten | - | - | - | - | - | - |

|

|

|

|

|

| |

| Klass B | Minutten | 68.1 | 73.1 | 78.1 | 82,8 | 87,8 | 92,8 |

|

|

|

|

|

| |

| Längt vum Fuedem b | - | - | - | - | - | - |

|

|

|

|

| |||

Fonctiounen a Virdeeler

Eis héichfest Sechskantschraube Din 931 / ISO4014 CL 8.8 ass eng Top-Befestigungsanlag, déi entwéckelt gouf fir déi héchst Qualitéits- a Leeschtungsnormen ze erfëllen. Dës Schraube huet eng Festigkeitsbewäertung vun 8.8, wat se perfekt mécht fir Uwendungen, déi en héije Grad un Haltbarkeet a Zouverlässegkeet erfuerderen.

Dëse Bolzen, deen aus Premium-Stol gemaach ass, ass korrosiouns- a Verschleissbeständeg a garantéiert eng laang Liewensdauer och ënner haarde Bedéngungen. Säi sechseckege Kapp erlaabt eng einfach Installatioun an Demontage mat engem Standardschlëssel oder enger Düsenschlüssel, während säin deelweise Gewëndedesign him e bessere Grëff a méi Haltkraaft gëtt.

Dëse Bolz ass gëeegent fir eng breet Palette vun industriellen an Bauapplikatiounen, dorënner Autoreparaturen, Maschinnemontage a strukturell Projeten. Seng Villsäitegkeet a Stäerkt maachen en zu enger Wiel fir Fachleit, déi eng zouverlässeg Befestigungsléisung brauchen, déi se net enttäuscht.

Wann Dir also e Befestigungselement braucht, dat den haardsten Konditioune standhält, da sidd Dir hei richteg op eis Héichfestigkeitssechskantschraube Din 931 / ISO4014 CL 8.8. Mat senger iwwerleeëner Qualitéit a Leeschtung bitt se sécher déi Haltbarkeet a Zouverlässegkeet, déi Dir braucht, fir d'Aarbecht richteg ze maachen.